New Delhi-based Trontek Electronics, which manufactures lithium-ion batteries, has been catering to the needs of electric two- and three-wheelers for some years now. With three plants in its portfolio, the company plans to increase this to five by the end of this calendar year.

Samrath S Kochar, Founder & CEO, Trontek, discusses in this interview why he remains upbeat about electric and how China will continue to dominate the arena in the years to come.

When did the Trontek Electronics journey begin?

We started as a lead-acid battery company. After completing my education, I joined my father’s electronics components business, but wanted to build something on a larger scale. Spotting strong demand for 12V UPS inverter batteries, we travelled to China, identified suppliers and imported a pilot batch of 500 units, which sold out quickly. Subsequent imports scaled rapidly, and the battery business grew steadily until 2010.We then entered the motorcycle battery segment, leveraging the same supplier base. The product scaled well in India, and by 2013–14, Trontek had established strong market recognition.

When the e-rickshaw wave emerged in 2013, we again sourced from China and launched dedicated batteries in India. Between 2013 and 2018, this became our hero product, earning the trust of fleet operators and OEMs through consistent performance.

Also Read: Three generations of Bajaj and the evolving Chetak story

Are these the same e-rickshaws we see across Delhi which are generally labelled China imports?

They were mostly Chinese imports then, but today most are made in India. By 2017, we started exploring lithium-ion batteries. We designed a lithium battery for e-rickshaws in China and brought it to India. It was nearly double the price of lead-acid, so we subsidised it initially – we absorbed ₹10,000 per battery and launched a pilot in Lucknow. Customers realised the benefits – no maintenance, longer life, consistency – and adoption grew.The real turning point was 2019, when the Government’s FAME policy mandated lithium batteries for subsidy eligibility. That is when two-wheeler OEMs also approached us for lithium packs. That marked the true start of our lithium-ion journey. In 2024, we began manufacturing our own BMS (battery management system) in-house, driven by localisation and guidelines policy push, which accelerated localisation and strengthened our technology capabilities.

Later, the government also mandated local chargers, and we now manufacture BMS and chargers in-house as well. Our next major initiative is a utility-scale BESS (battery energy storage system) container solution for the grid, for which we are setting up a new facility.

How do you view the inevitable China dependence?

The reality is that cells globally come from China. The ecosystem is massive and decades ahead. We source only cells from China now, and everything else is fully localised in India, significantly reducing risk.It is practically impossible to fully decouple from China today — this industry was built there, and the ecosystem for cells and materials is unmatched. China has also restricted the export of battery cell manufacturing machinery, and even those planning cell plants here must source technology from China.

Could you elaborate on your OEM relationships?

Of the top 10 OEMs, around five make their own packs – the remaining work with us. We supply to Ampere, BGauss, Kabra Group, among others. We previously supplied large volumes to Okinawa and Hero Electric, but after subsidy-related issues, both faced financial challenges that significantly impacted us.

Our revenues dropped from ₹600 crore to ₹300 crore, and there are still outstanding dues. However, we bounced back by diversifying and strengthening our three-wheeler portfolio, which today is our largest segment. We now supply to 200+ OEMs in the L3 (small) three-wheeler segment. Except Bajaj, TVS and a few others who make packs internally, almost every major L3 OEM buys from us. Three-wheeler batteries remain our ‘hero’ product.

We always prioritise scale customers — high-volume, high-reliability applications — where technology and performance truly matter. L3 remains our core focus. We are deeply embedded across the ecosystem comprising OEMs, dealers, and drivers, with a strong brand connection.

L3 and L5, which are the bigger EVs, will both be major growth drivers. From 2027, lead-acid batteries will be phased out of e-rickshaws, making the shift to lithium batteries irreversible.

Also Read: Industry seeks GST correction, duty relief for EVs ahead of Budget

Do you see EV momentum slowing down due to policy shifts around the world, which could impact momentum in India?

No, the EV revolution is already here, especially in commercial mobility. It makes strong economic sense. EVs are the future, particularly in commercial mobility. Electric is here to stay, and there is no real alternative in the near term.”

Do you see other clean fuels complementing electric?

Practically, electric has no true alternative in the near term. Hydrogen adoption will take much longer. Market dynamics are correcting with quality, engineering depth and long-term business fundamentals mattering more now.

Can you shed some light on your facilities and the work that takes place in each of them?

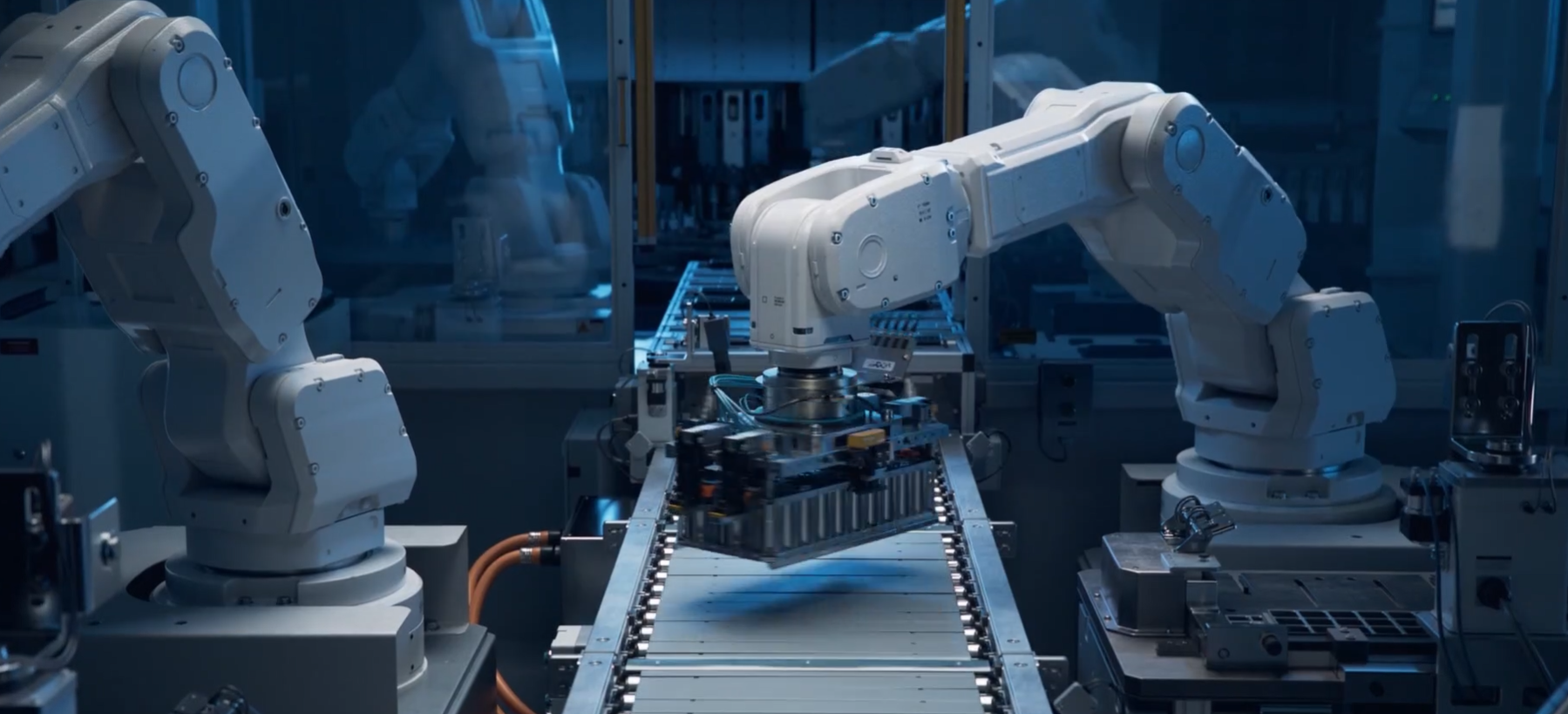

We have three factories today, with a fourth under development. One plant manufactures 50,000+ e-rickshaw batteries/month. Another produces 25,000 two-wheeler batteries/month. Our third unit houses BMS and charger manufacturing, and the head office, while the fourth plant near Gurugram will focus on BESS. Investment in the BESS plant alone is ₹50 crore, and the total recent capex is around ₹100 crore.

We are investing heavily in capacity expansion. Our fourth plant goes live next year, and a fifth plant is planned by 2026. Our five-year goal is to scale from ₹1,000 crore to ₹10,000 crore, driven by the shift from lead-acid to lithium across use-cases ranging from home inverters and telecom to mobility and storage.

What is next on the cards for Trontek?

Growth continues in two and three-wheelers, as well as BESS. We have also entered drone batteries. Passenger cars are not a target since OEMs make packs in-house. We plan to go public in 12–18 months, depending on timing and valuation. We are not in a hurry, but this will take time based on valuation and market conditions.

Are you contemplating any global expansion?

Yes, we are exploring exports and overseas manufacturing. We are evaluating a factory in the United States, particularly for golf-cart battery applications, which is a strong market segment there.

We are currently working with consultants on cost modelling, tariff impact, and site evaluation, including locations such as North or South Carolina. All this is under assessment, but we believe it is a strategic growth opportunity.

We are also assessing cost structures and tariff impacts before deciding whether it makes more sense to manufacture in India or build a plant overseas. While India remains our core base, we see clear potential in global niche battery markets, and we are preparing ourselves for that scale.

Have you considered manufacturing your own three-wheeler?

No. That would mean competing with our customers, something we will never do. We have seen others attempt it and lose trust.

- Published On Jan 16, 2026 at 01:33 PM IST

Join the community of 2M+ industry professionals.

Subscribe to Newsletter to get latest insights & analysis in your inbox.

All about ETAuto industry right on your smartphone!